Introduction

D2 steel, known for its exceptional properties and wide-ranging applications, stands as a cornerstone in various industries. This ultimate guide aims to provide a comprehensive exploration of D2 steel, delving into its properties, applications, and the myriad benefits it offers. Whether you’re a metallurgy enthusiast, a knife maker, or a manufacturing professional, this guide will equip you with valuable insights into the world of D2 steel.

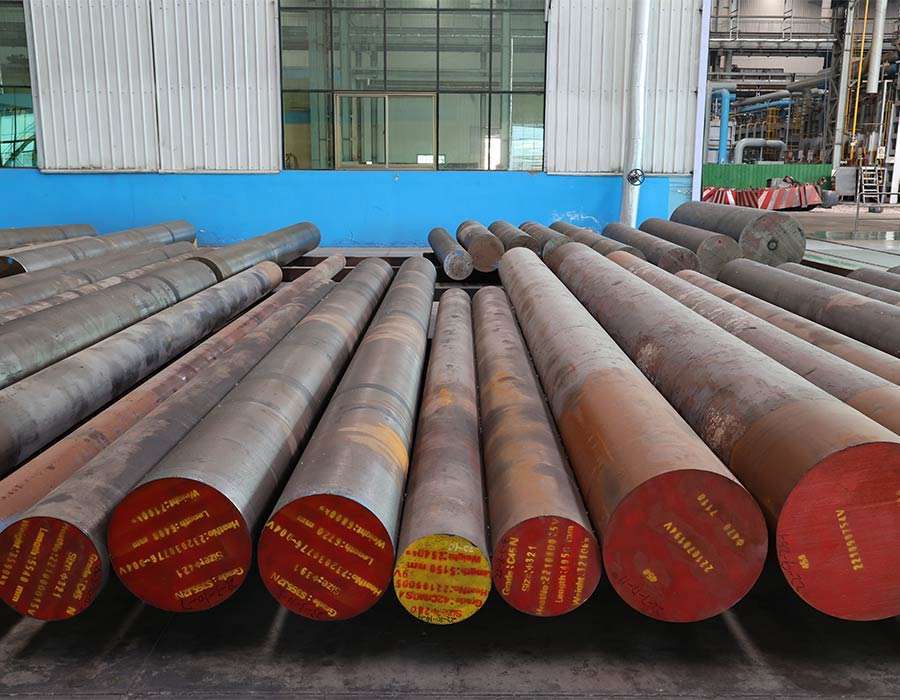

Properties of D2 Steel

D2 steel stands out in the realm of materials due to its exceptional properties, making it a coveted choice across a wide spectrum of industries and artisanal crafts. Its remarkable hardness, characterized by a high level of resistance to deformation and abrasion, renders it particularly well-suited for applications where durability is paramount. Whether employed in precision cutting tools or industrial machinery components, D2 steel’s ability to maintain its hardness under demanding conditions ensures consistent performance and longevity.

Moreover, D2 steel exhibits outstanding wear resistance, a quality that further enhances its appeal in various industrial and artisanal settings. This resistance to wear and tear translates to extended tool life and reduced maintenance requirements, contributing to enhanced efficiency and cost-effectiveness in manufacturing processes. Whether utilized in high-volume production environments or intricate handcrafted creations, D2 steel’s resilience against wear ensures reliable and consistent performance over time.

In addition to its hardness and wear resistance, D2 steel boasts excellent machinability, a feature that facilitates ease of shaping and forming during manufacturing processes. This machinability not only streamlines production workflows but also allows for intricate detailing and precise finishing, making D2 steel a preferred choice for applications that demand high levels of accuracy and intricacy.

Applications of D2 Steel

D2 steel’s versatility is a hallmark trait that finds its utility across a myriad of industries and sectors, demonstrating its adaptability and performance in a variety of demanding environments. Let’s delve into the diverse applications where D2 steel plays a pivotal role, showcasing its versatility and efficacy.

Precision Cutting Tools: In the realm of precision engineering and machining, D2 steel shines as a preferred material for manufacturing cutting tools such as drills, taps, reamers, and milling cutters. Its exceptional hardness and wear resistance ensure prolonged tool life and consistent performance, making it indispensable for high-precision operations in industries such as aerospace, automotive, and medical device manufacturing.

Industrial Molds and Dies: D2 steel’s remarkable properties make it an ideal choice for fabricating molds and dies used in injection molding, extrusion, and stamping processes. Its high hardness and dimensional stability enable the production of intricate and complex molds that can withstand the rigors of repeated use and maintain precise tolerances. From automotive components to consumer electronics, D2 steel molds and dies play a critical role in mass production processes across various industries.

Metal Forming and Forging: D2 steel’s toughness and resistance to deformation make it well-suited for applications in metal forming and forging, where high impact and compressive forces are prevalent. Whether used in forging dies, punches, or hot working tools, D2 steel exhibits excellent performance in shaping and manipulating metal alloys, contributing to efficient and precise manufacturing processes in industries such as aerospace, defense, and heavy machinery.

Benefits of D2 Steel

The advantages of D2 steel are multifaceted, making it an attractive option for craftsmen and manufacturers alike. Let’s explore the myriad benefits that D2 steel brings to the table, empowering businesses and artisans to make informed decisions when choosing materials for their projects.

Durability: One of the standout features of D2 steel is its exceptional durability. Engineered to withstand rigorous use and harsh conditions, D2 steel exhibits robustness that ensures longevity and reliability in various applications. Whether employed in cutting tools, molds, or dies, D2 steel’s durability translates to enhanced performance and prolonged service life, reducing the need for frequent replacements and maintenance.

Edge Retention: D2 steel’s ability to maintain a sharp cutting edge over extended periods is another notable advantage. This attribute is particularly valuable in applications where precision and consistency are paramount, such as in woodworking, metalworking, and plastics processing. By retaining its sharpness, D2 steel ensures clean and accurate cuts, resulting in higher productivity and superior quality in finished products.

Corrosion Resistance: Despite being a tool steel, D2 steel exhibits commendable resistance to corrosion, making it suitable for use in environments where exposure to moisture, chemicals, or harsh elements is prevalent. This corrosion resistance minimizes the risk of rust and degradation, preserving the integrity and aesthetics of tools, components, and finished products over time. Whether utilized indoors or outdoors, D2 steel’s resistance to corrosion enhances its suitability for a wide range of applications.

Working with D2 Steel: Tips and Techniques

While D2 steel offers exceptional performance, working with it requires careful consideration and adherence to best practices. This section provides practical tips and techniques for machining, heat treating, and finishing D2 steel, ensuring optimal results and longevity in various applications.

| Process | Tips and Techniques |

|---|---|

| Machining | – Use sharp cutting tools with high cutting speeds and feeds to minimize heat buildup and tool wear. |

| – Employ coolant or lubricant to dissipate heat and improve chip evacuation during machining. | |

| – Maintain proper tool geometry and ensure rigidity of setup to prevent chatter and vibration. | |

| Heat Treating | – Preheat D2 steel uniformly to the desired temperature before quenching to minimize distortion. |

| – Quench rapidly in oil or air to achieve desired hardness, followed by tempering to relieve stress. | |

| – Monitor temperatures carefully to avoid overheating and ensure uniform heat treatment. | |

| Finishing | – Use abrasives with appropriate grit size and hardness for grinding and polishing D2 steel surfaces. |

| – Apply a protective coating or passivation treatment to enhance corrosion resistance post-finishing. | |

| – Inspect finished components for surface defects and dimensional accuracy before final application. |

Conclusion

In conclusion, D2 steel stands as a versatile and reliable material that continues to leave an indelible mark across industries worldwide. Its exceptional properties, diverse applications, and numerous benefits underscore its significance in modern manufacturing and craftsmanship. As businesses and artisans alike continue to harness the potential of D2 steel, its legacy as a premier material of choice is destined to endure.

FAQ

Q: What is D2 steel primarily used for?

A: D2 steel finds applications in a wide range of industries, including tool and die making, knife manufacturing, industrial cutting, and metal forming.

Q: What are the key properties of D2 steel?

A: D2 steel is known for its high hardness, excellent wear resistance, good machinability, and dimensional stability.

Q: How does D2 steel compare to other tool steels?

A: D2 steel offers superior wear resistance and edge retention compared to many other tool steels, making it well-suited for applications requiring prolonged use and high cutting performance.

Q: Is D2 steel susceptible to corrosion?

A: While D2 steel exhibits good corrosion resistance, proper care and maintenance are still essential to prevent rust and degradation, especially in harsh environments.