Introduction

Alloy steel is a cornerstone in the realm of industrial applications due to its remarkable strength, versatility, and durability. One of the most critical properties of alloy steel that determines its suitability for various applications is its yield strength. Alloy steel yield strength refers to the maximum stress that alloy steel can withstand without permanent deformation. This comprehensive guide explores the impact of alloy steel yield strength on industrial performance, its significance, factors influencing it, and its applications across different sectors.

Understanding Alloy Steel Yield Strength

What is Alloy Steel Yield Strength?

Alloy steel yield strength is the stress at which a material begins to deform plastically. Before reaching the yield point, the material will deform elastically, meaning it will return to its original shape when the applied stress is removed. Beyond the yield point, permanent deformation occurs.

- Definition: Stress level at which material deforms plastically

- Elastic Deformation: Reversible changes in shape

- Plastic Deformation: Permanent changes in shape

Importance of Alloy Steel Yield Strength

The yield strength of alloy steel is crucial because it determines the load that the material can handle before it undergoes permanent deformation. This property is essential for ensuring the safety and integrity of structures and components.

- Load-Bearing Capacity: Determines maximum load before permanent deformation

- Structural Integrity: Ensures safety and durability of structures

- Material Selection: Influences choice of material for specific applications

Factors Affecting Alloy Steel Yield Strength

Several factors can influence the yield strength of alloy steel, including its chemical composition, heat treatment, and manufacturing process.

- Chemical Composition: Elements like carbon, manganese, and chromium affect strength

- Heat Treatment: Processes like quenching and tempering can enhance yield strength

- Manufacturing Process: Techniques like forging and rolling impact material properties

Table: Factors Influencing Alloy Steel Yield Strength

| Factor | Description |

|---|---|

| Chemical Composition | Elements such as carbon, manganese, and chromium |

| Heat Treatment | Processes like quenching, tempering, and annealing |

| Manufacturing Process | Methods such as forging, rolling, and casting |

| Grain Size | Smaller grain size usually increases yield strength |

| Temperature | Yield strength decreases at higher temperatures |

| Alloying Elements | Additives like nickel, molybdenum, and vanadium |

The Impact of Alloy Steel Yield Strength on Industrial Performance

-

Alloy Steel 31CrMoV9/1.8519

Alloy Steel 31CrMoV9/1.8519 -

Alloy Steel 17CrNiMo6/1.6587

Alloy Steel 17CrNiMo6/1.6587 -

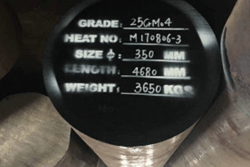

Alloy Steel 25CrMo4/1.7218/SCM430

Alloy Steel 25CrMo4/1.7218/SCM430 -

Alloy Steel 8620/1.6523/20CrNiMoA/SNCM220

Alloy Steel 8620/1.6523/20CrNiMoA/SNCM220 -

Alloy Steel 18CrNiMo7-6/17CrNiMo6/1.6587

Alloy Steel 18CrNiMo7-6/17CrNiMo6/1.6587 -

Alloy Steel 18CrMo4/1.7243

Alloy Steel 18CrMo4/1.7243 -

Alloy Steel 30CrNiMo8/1.6580

Alloy Steel 30CrNiMo8/1.6580 -

Alloy Steel 36CrNiMo4/1.6511/SNCM439/EN24

Alloy Steel 36CrNiMo4/1.6511/SNCM439/EN24 -

Alloy Steel 34CrNiMo6/1.6582

Alloy Steel 34CrNiMo6/1.6582

Construction Industry

In the construction industry, alloy steel with high yield strength is used to ensure the structural integrity and longevity of buildings, bridges, and other infrastructure projects. The ability to withstand heavy loads without permanent deformation is crucial for safety and durability.

- Buildings: Structural beams, columns, and reinforcements

- Bridges: Load-bearing components that ensure stability

- Infrastructure: Pipelines, frames, and support structures

Automotive Industry

Alloy steel yield strength plays a significant role in the automotive industry, where components are subjected to high stresses and loads. Materials with high yield strength ensure that parts such as chassis, engine components, and suspension systems can withstand the demands of everyday use and harsh conditions.

- Chassis: Ensures vehicle rigidity and safety

- Engine Components: Withstands high pressures and temperatures

- Suspension Systems: Provides durability and performance

Aerospace Industry

In the aerospace industry, the high yield strength of alloy steel is essential for components that must endure extreme stresses and temperatures. The ability to maintain structural integrity under these conditions is critical for the safety and performance of aircraft.

- Aircraft Frames: Ensures structural stability and safety

- Engine Parts: Withstands high temperatures and pressures

- Landing Gear: Provides strength and durability during landing

Oil and Gas Industry

The oil and gas industry relies on alloy steel with high yield strength for drilling equipment, pipelines, and structural components. These materials must withstand high pressures, temperatures, and corrosive environments to ensure efficient and safe operations.

- Drilling Equipment: High-strength steel for durability and performance

- Pipelines: Withstands high pressures and corrosive conditions

- Structural Components: Ensures safety and stability of platforms and rigs

Manufacturing Industry

In the manufacturing industry, machinery and tools made from alloy steel with high yield strength ensure longevity and reliability. These materials can handle the stresses and loads associated with heavy-duty manufacturing processes.

- Machinery: High-strength components for durability

- Tools: Ensures long-lasting performance under high stress

- Industrial Equipment: Provides reliability and efficiency

Enhancing Alloy Steel Yield Strength

Heat Treatment Processes

Heat treatment processes such as quenching, tempering, and annealing are commonly used to enhance the yield strength of alloy steel. These processes involve heating the steel to specific temperatures and then cooling it at controlled rates to alter its microstructure and mechanical properties.

- Quenching: Rapid cooling to increase hardness and strength

- Tempering: Heating to a moderate temperature to reduce brittleness

- Annealing: Slow cooling to soften the material and improve ductility

Alloying Elements

Adding alloying elements such as chromium, nickel, molybdenum, and vanadium can significantly enhance the yield strength of steel. These elements modify the steel’s microstructure, increasing its resistance to deformation and improving its mechanical properties.

- Chromium: Increases hardness and corrosion resistance

- Nickel: Enhances toughness and strength

- Molybdenum: Improves high-temperature strength and hardness

- Vanadium: Increases yield strength and toughness

Grain Size Refinement

Refining the grain size of alloy steel through processes such as controlled rolling and forging can enhance its yield strength. Finer grain structures provide more grain boundaries, which impede dislocation movement and increase strength.

- Controlled Rolling: Produces fine grain structure

- Forging: Refines grain size and enhances mechanical properties

Cold Working

Cold working, or work hardening, involves deforming the steel at room temperature to increase its yield strength. This process introduces dislocations in the microstructure, which impede further dislocation movement and increase strength.

- Cold Rolling: Reduces thickness and increases strength

- Drawing: Pulls steel through a die to increase hardness

Conclusion

Alloy steel yield strength is a critical property that impacts the performance and reliability of various industrial applications. From construction and automotive to aerospace and oil and gas, the high yield strength of alloy steel ensures that components can withstand significant stresses and loads without permanent deformation. By understanding the factors that influence yield strength and employing techniques to enhance it, industries can optimize their use of alloy steel to achieve superior performance and safety.

FAQ

What is alloy steel yield strength?

Alloy steel yield strength is the stress at which alloy steel begins to deform plastically. It indicates the maximum stress the material can withstand without undergoing permanent deformation.

How does alloy steel yield strength affect industrial performance?

Alloy steel yield strength affects industrial performance by determining the load-bearing capacity of components. High yield strength ensures that parts can handle significant stresses and loads without permanent deformation, enhancing safety and reliability.

What factors influence alloy steel yield strength?

Factors that influence alloy steel yield strength include chemical composition, heat treatment processes, manufacturing methods, grain size, temperature, and the presence of alloying elements.

How can the yield strength of alloy steel be enhanced?

The yield strength of alloy steel can be enhanced through heat treatment processes such as quenching and tempering, adding alloying elements like chromium and nickel, refining grain size, and cold working.

Why is alloy steel yield strength important in the construction industry?

In the construction industry, alloy steel yield strength is important because it ensures the structural integrity and longevity of buildings, bridges, and other infrastructure projects. High yield strength allows structures to withstand heavy loads without permanent deformation.

How does yield strength differ between various types of alloy steel?

Yield strength can vary significantly between different types of alloy steel depending on their chemical composition, heat treatment, and manufacturing process. For example, high-strength low-alloy (HSLA) steels typically have higher yield strength than carbon steels.

What role does heat treatment play in enhancing alloy steel yield strength?

Heat treatment processes such as quenching, tempering, and annealing alter the microstructure of alloy steel, enhancing its mechanical properties, including yield strength. These processes involve controlled heating and cooling to achieve desired strength levels.

Can the yield strength of alloy steel be measured accurately?

Yes, the yield strength of alloy steel can be measured accurately using mechanical testing methods such as tensile testing. This involves applying a controlled load to a sample until it deforms, and recording the stress at which plastic deformation begins.

What is the impact of temperature on alloy steel yield strength?

Temperature can significantly impact alloy steel yield strength. Generally, yield strength decreases at higher temperatures because the material becomes more ductile and less resistant to deformation.

How does cold working increase alloy steel yield strength?

Cold working, or work hardening, increases alloy steel yield strength by introducing dislocations in the microstructure during deformation at room temperature. These dislocations impede further movement, increasing the material’s resistance to deformation and enhancing its strength.